Flexomaster-HR-500 Model

The New Generation of CI FLEXO PRESS is a compact design with mechanical rigidity for a wide range of Flexible Packaging Jobs with several operational efficiency.

Salient Features:

- Latest Gearless Technology.

- Non Stop Turret. Auto Splice In Unwind & Rewind With Touch Screen Control.

- PLC Programmable Ink Management (Inking & Washing Up).

- PLC Controlled Fast Changeover which enables to open all stations in max. 20 seconds and releases all sleeves at same time.

- Carbon Fibre technology used in Closed Chambered Doctor Blade, Plate Roller & Anilox Roller Cylinder.

- High Efficiency Drying System according to machine speed.

- Recipe Based Management For All machine speed.

- LEL system for Automatic control of Solvent Retention.

- Portable control panels at Print Sections and along the Press.

- LECO (Learning Error Compensation Technology) System (Optional).

- Automatic Pre register control system for fast job set up.

- Automatic Deck Positioning Control.

- User-friendly Touch Key operation.

- Automatic Video scanning system.

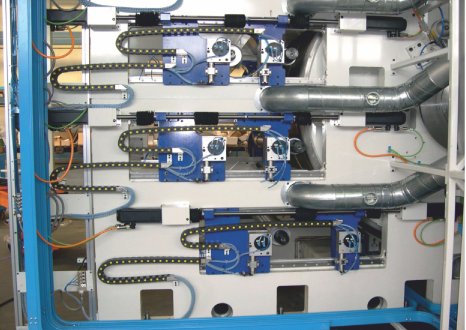

Electric Control Cabinet (Electrical Container)

- An electric container is supplied as a walk in control board, for all the electrical and electronic control of the machine.

- Full size maritime container for electric components.

- The electric container is thermally insulated and air- conditioned.

- The machine main switch is located at the entrance of the electric container.

- Inspection platform at the electric container level.

Main Control Console

- PC/PLC based control sequences.

- The computer control console allows the operator to manage the machine entirely, by controlling for the production parameters to setting up for the job to follow.

- All necessary switches, button and display necessary to operate the machine are located on the console.

- The Remote Control Service is provide for quick service solution of the machine at any place in the world.

Automatic Turret Winders with Flying Splice

- Shafted or shaftless winder turret, fabricated steel frames 100mm (4”) designed to allow the top speed operations.

- Self-locking chucks, to lock the winding shafts at the rotation of the reel.

- PLC controlled sequence for reel splice on both unwinder and rewiner.

- Automatic positioning of new reel at splice on the unwinder.

- Print cylinder throw-off in sequence to the splice at the wunwinder.

- By directional flying splice procedure controlled by and AC motor.

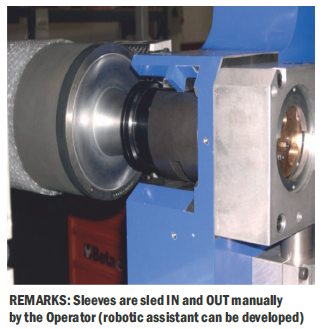

Easylock (patented)

Automatic sleeve changing by EASYLOCK (patented)

- Automatic, programmable sleeve lock-unlock sequence for extremely fast sleeves change over.

- All enable stations operate at the same time for both print cylinders and anilox rollers.

- Max 20 seconds to open all stations are release all sleeves at the same time, ALTOGETHER

- Same time and sequence to close stations and lock the sleeves supports.

Ink Management with Auto Wash

- A high level of automatic system that manages the ink supply to the print section and cleans the ink chamber, the anilox, ink tanks and connection hoses in the circuit.

- The system includes built-in online viscometers to automatically regulate the viscosity in the values set up as optimum for printing and also includes tanks for the solvent that connect to solvent recovery equipment, achieving safe and fully automatic operation

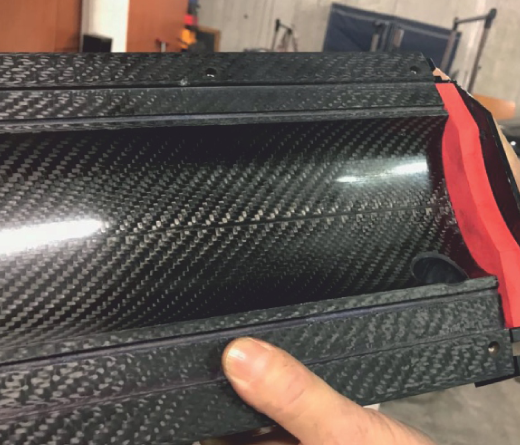

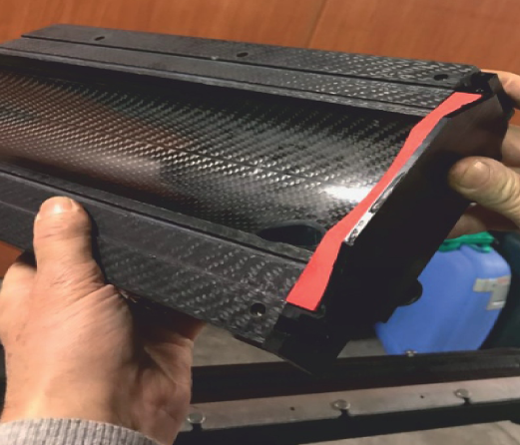

Carbon Fibre Chambered Doctor Blade

- Echaar's Doctor Blade system is assembled in a closed swinging chamber which is a Carbon Fibre Technology.

- It is pneumatically controlled on both sides and has independent adjustment in each side.

- Doctor blade has a tool-free changeover system, so that the users can obtain a fast and safe blade and seal changeover.

- In this technology the ink doesn't stick to the doctor blade fibre and the wash up procedure requires less solvent and shorter wash up time.

Contact Us

Plot No. A-48/49, Road No.10,

Wagle Industrial Estate,

Thane – 400 604.

Maharashtra, India.

T : +91-22-25806683, 2580 2240

F : +91-22-2583 2866

E : info@echaar.com

W : www.echaar.com

Help?

Call us now on

022 2580 6683

022 2580 2240

Website created and maintained by advice communication

Copyright © 2018 Echaar